Usage:Outdoor Grade:First-Class Main Material:Poplar

Usage:Outdoor

Grade:First-Class

Main Material:Poplar

Formaldehyde Emission Standards:E0

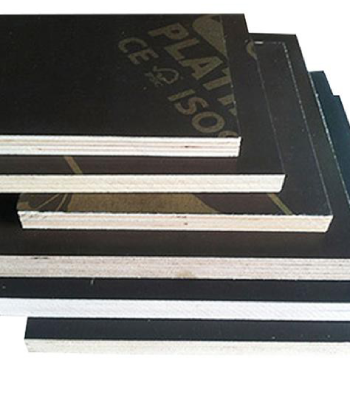

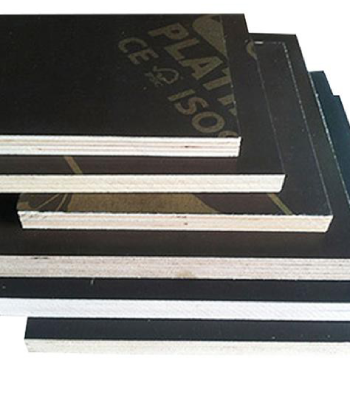

Product name:Film faced plywood

Core:Poplar

Face/back:Phenoli paper film;dynea;enso;local;smooth;ultra brighten

Size:1220mm*2440mm(accept customization)

Thickness:12MM~35MM

Glue:Phenolic WBP glue

Application:Construction formwork;template,mold;shuttering;decking;special packing

Certification:CE,CARB,FSC,ISO9001

Moisture:8%-12%

Product Name | 1220mm*2440mm poplar film faced plywood for concrete shuttering |

Size | 1.small sizes:915x2135mm,1525x1525mm 2.standard sizes:1220X2440mm, 1250x2500mm 3.big size:1500x3000mm,(accept customization) |

Thickness | 12MM~25MM |

Core | Peeing veneer;poplar;combi;eucalyptus;birch;pine;meranti; other hardwood;or finger joint core; |

Face&Back | Phenolic paper film; Dynea/Enso/local; smooth/ ultra brighten/antislip(wire mesh,anti-skid) |

Glue | phenolic formaldehyde adhesive(PF); melamine WBP glue(MUF) |

Emission Content Of Formaldehyde | E0(PF glue);E1/E2(MUF) |

Usage | construction/concrete formwork/template/shuttering; decking; special packing |

Layers | 15mm(9/11ply),18mm(11,13,15ply) |

Certificate | CE,CARB,FSC,ISO9001 |

Moisture Content | 8%-12% |

Payment | L/C at sight, TT as deposit |

Advantages

1. If put in boiling water for 48 hours, it is still glue-sticking and non-deformed

2. Physical mood is better than iron moulds and can satisfy the requirements of constructing mould, the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing

3. If used abide by the illustrations strictly, it can be reused more than 50 times,

4. Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould)

5. Solves the problems of leaking and rough surface during constructing process

6. Particularly suitable for watering concrete project , can make the concrete surface smooth and flat

7. Realizing a higher economic profits.