Model Number:1220*2440mm Usage:Outdoor Grade:First-Class

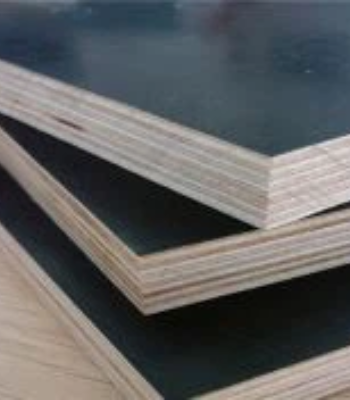

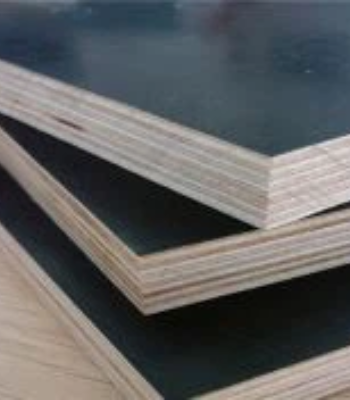

Item Name:Best Price 12MM Shuttering Plywood

Siza:1220mmX2440mm

Thickness:9mm~25mm

Thickenss tolerance:+/0.2mm(thickness<6mm),+/-0.3~0.5mm(thickenss>6mm)

Face&Back:Water proof film plastic

Surface Treatment:Black or Brwon film

Core:poplar,hardwood

Glue:MR,

Grade:Construction Grade

Density:530~650Kgs/cbm

Moisture conetent:10%~15%

Water Absorption:?10%

Standard packping:Inner packing-pallet is wrapped with 0.20mm plastic bag

Outer parcking-pallets are covered with plywood or carton boxes,and strong steel belts

Loading Quantity:20'GP GP-8pallets/22cbm, 40’HQ-18pallets/50cbm or upon request

MOQ:1x20'FCL

Supply Ability:5000CBM/Month

Payment terms:T/T or L/C

Delivery time:Within 2~3 weeks upon down payment or upon opening of L/C

Marks:Decoration Use,Red veneer,furniture,good price with good quality.main market is asia

The plywood raw materials are soft wood, such as poplar, pine, birch wood,Eucalyptus wood,maple wood. then use the peeling machine to peel the wood skin. then slice cut, then after dying the wood chips finished. then glue core veneer. after that use cold pressing, hot pressing ,wood putty sanding,pressing face veneer,cold pressing,hot pressing,sanding,cutting edges, the plywood finished.

Advantages:

1. If put in boiling water for 48 hours, it is still glue-sticking and non-deformed

2. Physical mood is better than iron moulds and can satisfy the requirements of constructing mould,

the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing

3. If used abide by the illustrations strictly, it can be reused more than 50 times,

4. Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould)

5. Solves the problems of leaking and rough surface during constructing process

6. Particularly suitable for watering concrete project , can make the concrete surface smooth and flat

7. Realizing a higher economic profits.